Product

Desiccant air dryers

Air treatment, a crucial investment

Compressed air contains oil, solid particles and water vapors. Together, they form an abrasive, often acidic, oily sludge. Without air treatment, this murky mix will enter your compressed air system, corroding pipe work, damaging pneumatic tools and potentially compromising final products.

Quality air applications

Dry and clean compressed air, produced reliably and efficiently, is essential for a broad range of industrial applications.

- Oil & Gas - Especially off-shore installations require full production protection with a continuous supply of dry compressed air, available 24/7 at a low dewpoint.

- Food & Beverage - Any kind of moisture must be removed from the preparation and processing of food and beverages to ensure free and easy movement of ingredients and products.

- Pharmaceuticals - Eliminating any moisture is critical in the processing and manufacturing of most pharmaceuticals as some materials have a physical affinity for moisture.

Safeguard your production and your reputation

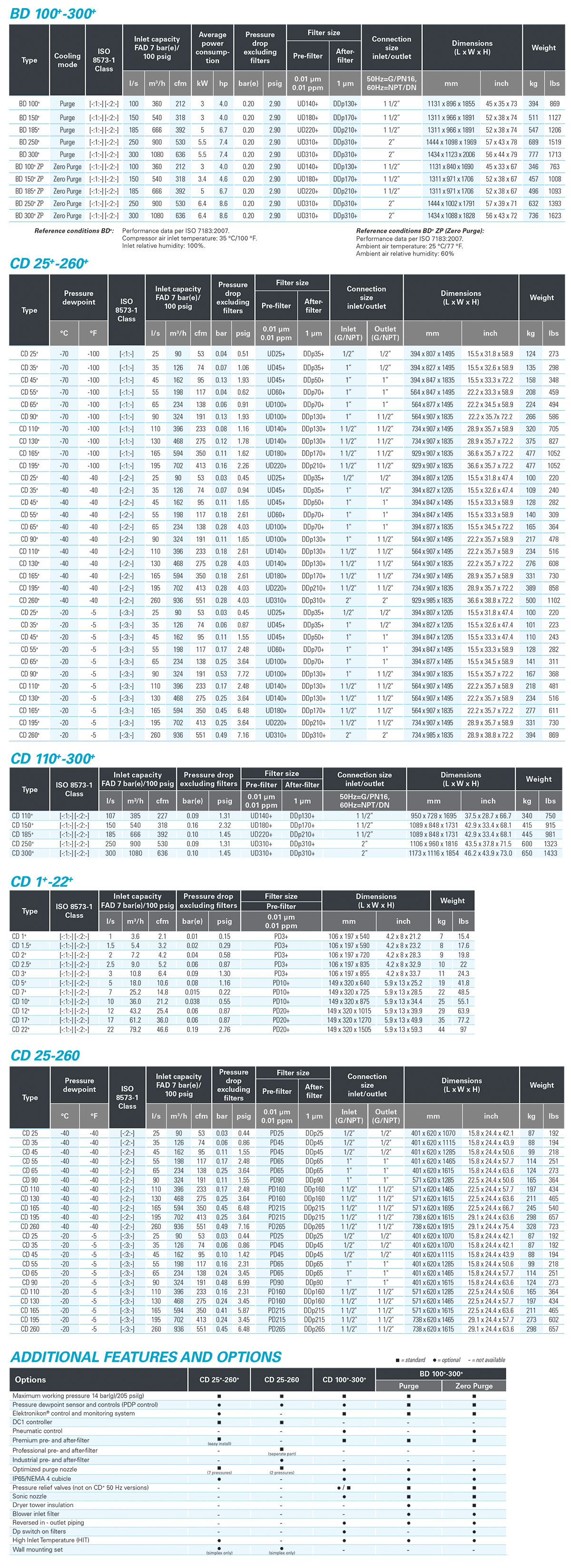

Atlas Copco desiccant dryers protect the reliability of your production and the quality of your products. The high-performance dryers remove the moisture from your compressed air with a standard pressure dewpoint of -20 °C/-5 °F, -40 °C/-40 °F and -70 °C/-100 °F for complete peace of mind, at the dewpoint per unit your individual applications require.

Enjoy easy installation and long maintenance intervals

Thanks to their compact all-in-one design, the dryers are an unobtrusive presence on your production floor. Delivered ready for use, their installation is quick and easy. All internal components are readily accessible to facilitate maintenance. The high-grade desiccant and durable valves extend maintenance intervals beyond the standard three years.

Meet your specific requirements

Atlas Copco desiccant dryers offer the right air quality for your application with pressure dewpoints as low as -70 °C/-100 °F or ISO Class [-:1:-].

Set new quality standards

Tested according to ISO 7183:2007, Atlas Copco desiccant dryers meet and often exceed international standards for compressed air purity. Naturally, all our dryers provide full protection of electrical components, controls and displays.

Drive down energy costs

Atlas Copco desiccant dryers come with a range of energy-saving features that cut your carbon footprint.

- A pressure drop below 0.2 bar/2.9 psi drives down energy costs.

- Dewpoint sensing and control adapt energy consumption to the real load of the dryer.

- An adjustable dewpoint enables you to adapt the dryer to your actual needs.

How do desiccant dryers work?

Desiccant dryers consist of two towers filled with desiccant such as activated alumina, molecular sieves or silica gel. Wet compressed air passes directly through the substance, which adsorbs the moisture. The desiccant has a finite adsorption capacity before it must be dried out. Hence the twin tower design. While one tower is drying air, the other is being regenerated.

With the BD+ blower (zero) purge dryers and CD(+) heatless desiccant dryer series, Atlas Copco offers a desiccant drying solution to meet your exact needs.

- 1. Drying Wet compressed air flows upward through the adsorbent desiccant from bottom to top (1).

- 2. Regeneration Heatless desiccant dryers – CD+: Dry air from the drying tower outlet is expanded to atmospheric pressure and sent through the saturated desiccant, forcing the adsorbed moisture out (2 and 4). After desorption, the blow-off valve is closed and the vessel is re-pressurized. Blower (zero) purge desiccant dryers – BD+: The blower (5) takes ambient air and blows it across the external heater (6). The heated air is then sent through the saturated desiccant (2), forcing the adsorbed moisture out.

- 3. Cooling (BD+) BD+ with purge: After the heating phase, the desiccant is cooled by expanding dry compressed air from the outlet of the adsorbing vessel over the hot reactivated tower. BD+ with zero purge: After the heating phase, the blower takes in ambient air and sends it through the reactivated tower from bottom to top.

- 4. Switching After regeneration, drying switches from the saturated tower to the regenerated tower (3).

- Which Atlas Copco desiccant dryer is right for you? Atlas Copco offers two types of desiccant dryers, the BD+ range of blower (zero) purge dryers and the CD(+) series of heatless desiccant dryers. The difference lies in their regeneration process.

Site conditions

Because of their simple design, heatless desiccant dryers are often preferred for extreme environments. This includes remote areas, hazardous sites with explosive gases and powders, and applications with a high inlet air temperature.

Lifecycle cost

A heatless desiccant dryer is more expensive to own because it uses a high amount of compressed air for purging during regeneration. Typically, purge air takes up 16% to 19% of the rated flow capacity of a heatless dryer. However, the heatless dryer remains a popular choice because of its simplicity and reliability.

Superior energy efficiency

A dryer's energy consumption is determined by its internal pressure drop and the efficiency of its regeneration process. If a desiccant dryer experiences a high pressure drop, the compressor discharge pressure must be set higher, which increases energy and operating costs. Atlas Copco BD+ and CD(+) desiccant dryers offer a very low pressure drop – below 0.2 bar/2.9 psi for most models – as well as the most efficient regeneration process.

Dewpoint Dependent Switching for energy savings up to 90%

Atlas Copco's BD+ and CD(+) desiccant dryers incorporate state-of-the-art energy management control with built-in Dewpoint Dependent Switching. The principle is simple. A dewpoint sensor will delay switching towers until dryer conditions require it. This cycle time extension can generate energy savings of up to 90%.

Blower (zero) purge desiccant dryers

Looking for the desiccant dryer with the lowest operating costs? The BD+ Zero Purge is your best choice. With zero purge losses and minimal electricity use, the BD+ ZP offers the highest energy savings. Our lifecycle cost comparison on page 5 quantifies the differences.

- Highest efficiency for continuous operation CD 25+-260+

- 1. High-efficiency operation

- 2. Advanced energy savings

- 3. Unique manifold/valve design

- 4. New silencing design

- 5. Advanced control and monitoring system

- 6. Service and maintenance-friendly

- 7. Integrated filters

- 8. Nozzle purge set

Offers flexibility in optimizing regeneration pressure. Standard is 7 bar; 4-bar, 5.5-bar, 8.5-bar, 10-bar, 11.5-bar, 13 and 14-bar nozzles come as separate parts.

Heatless desiccant dryers

- 1. Quality desiccant

- 2. Stainless steel valves

- 3. Upsized silencers

- 4. Galvanized piping with flanged connections

- 5. Filters

- 6. Advanced control and monitoring system

- 7. Dewpoint Dependent Switching

- 8. Robust and compact design

Features & Benefits

- 1. High-quality components

- 2. High-performance molecular sieves

- 3. Multi-port inlet and outlet

- 4. Integrated silencers

- 5. Full electronic controller

Full electronic controller with purge saver function. The sophisticated electrical panel is IP65-protected against water and dust.

Enduring performance

- Non-return valves and purge cavities are built into the polycarbonate cartridges.

- Each desiccant cartridge includes an integrated after-filter to save space, simplify installation and decrease the risk of leaks.

- The dryer can perform in working pressures up to 16 bar(g)/232 psig and temperatures up to 50 °C/122 °F.

Energy efficiency and savings

- Low pressure drop across the whole range.

- Purge saver function is included as standard.

- Adjustable purge, available as an option, matches purge air consumption to the actual working conditions.

Easy operation

- Controller shows the dryer/cycle status and automatic fault diagnosis.

- No need to disconnect the dryer from the compressed air network for servicing.

- The inlet and outlet can be reversed. The dryer can be operated remotely.

Competitive investment & superb reliability CD 25-260

- 1. Reliable operation

- 2. Unique manifold/valve design

- 3. Advanced control and monitoring system

- 4. Service and maintenance-friendly

- 5. Attached filters

- 6. Nozzle purge set

- 7. Advanced options

Committed to Sustainable Productivity

We stand by our responsibilities towards our customers, towards the environment and the people around us. We make performance stand the test of time. This is what we call – Sustainable Productivity.

Contact us

- +91 7977990375

- airkomagencies@gmail.com